06 February 2019

What’s the right choice?

The safety of thermal disinfection, affordable to all.

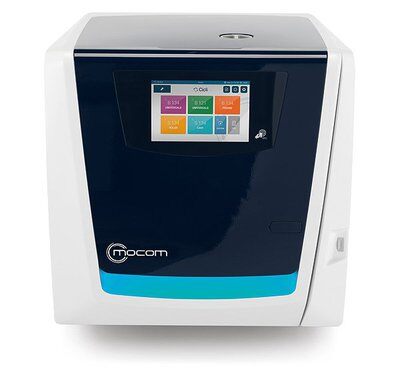

In everyday professional dentistry, equipping the surgery with a thermal disinfector that allows effective removal of dirt and perfect instrument disinfection in a single cycle represents a smart move indeed!

The safety of thermal disinfection, affordable to all.

Every day, in dental practices everywhere, both dentists and assistants repeatedly need to handle considerable quantities of instruments and materials during the sterilization process. Since most surgical instruments are, by definition, pointed or sharp, the risk of accidental contamination during the handling that occurs as part of washing and the removal of stubborn organic/inorganic residue is considerably high. Moreover, washing and disinfection is often done manually in sinks using simple tools (brushes, bowls with liquid detergent/disinfectant, ultrasound trays etc.), thus making any kind of process control or consistency difficult, which raises risk levels even higher.

Lastly, the entire zone in which these tasks take place risks becoming highly contaminated on a permanent basis in that the open nature of the environment means splashes, solid particles and mist can easily spread over an extensive area (without, in most cases, the staff being aware of it).

So, what’s the right solution?

To equip the surgery with a thermal disinfector that, in a single automatic cycle, effectively removes dirt and disinfects instruments perfectly thanks to a high-temperature wash process, executed in compliance with ISO EN 15883; this reduces the probability of any microorganisms being present on the load to a completely safe level that is fully compatible with those tasks normally carried out by skilled, trained personnel.

Because the process takes place in an isolated environment (a watertight wash compartment) the chances of any workplace contamination are extremely limited. Once removed from the device, instruments can be handled by health workers safely during the subsequent packaging and sterilization tasks.

Fully automatic operation, electronically controlled using high precision sensors, ensures long-lasting result consistency, cycle after cycle, thus removing the “human error factor” and reducing risk to zero. In practice, this means less stress for personnel, greater comfort thanks to the elimination of manual tasks and an overall safety level that is far beyond the reach of other systems.

Share on...