06 March 2019

Always one step ahead

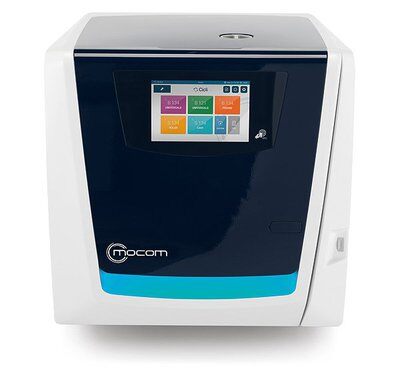

Sterilization comes first, there is no doubt about it. But every process can be improved, and every enhanced aspect brings enormous benefits to the dental surgery. When renewing its range, Mocom wanted to exceed expectations. Here’s how it succeeded.

Tap water means convenience and major savings. With the top-of-the-range model, Supreme, the goal of recovering and reusing water has been reached. Supreme reshapes the sterilization world. Minimum consumption rates. While normally 5 litres would barely be enough for 8 cycles, Supreme uses the same amount for up to 50 cycles, that is 100ml/cycle. A full-fledged revolution. It is the first closed-loop sterilizer that uses mains water through a specific internal filtration system that recycles water thus making it possible to reuse it in the following cycles. This performance eliminates waste, reduces costs and ensures a significant increase in the efficiency of any modern dental surgery.

B Futura, already known for its outstanding performance, is now equipped as standard with Wi-Fi connectivity and integrated demineralisation system and offers the possibility to download cycle data directly on a connected PC.

Connected to the Internet by enabling the Easy Check service, these two models can receive remote support, while Di.V.A. (Digital Virtual Assistant) provides the first cloud-based control and traceability system for Mocom sterilization devices.

The range is complemented by the sterilizers B Classic and B Now, as well as by thermal sealers, ultrasound tanks, thermal disinfectors, and Tethys H10 Plus, a revolutionary device that performs decontamination, washing, thermal disinfection and drying in a single automated process. One cycle that eliminates all risks for the operator and efficiently completes the four phases that precede instruments’ wrapping and sterilization.

Share on...